Proof of concept:

Previous versions of the IFD-175 have proven that the concept of in-line filament drying is feasible. The challenge with the AP model was whether it can keep up with the latest high speed printers and high temperature filaments. We’ve found that testing by weight is the most effective and repeatable method of measuring the dryness of filament. The charts below use 25 common types of filament. The parameters for each testing method are noted in data.

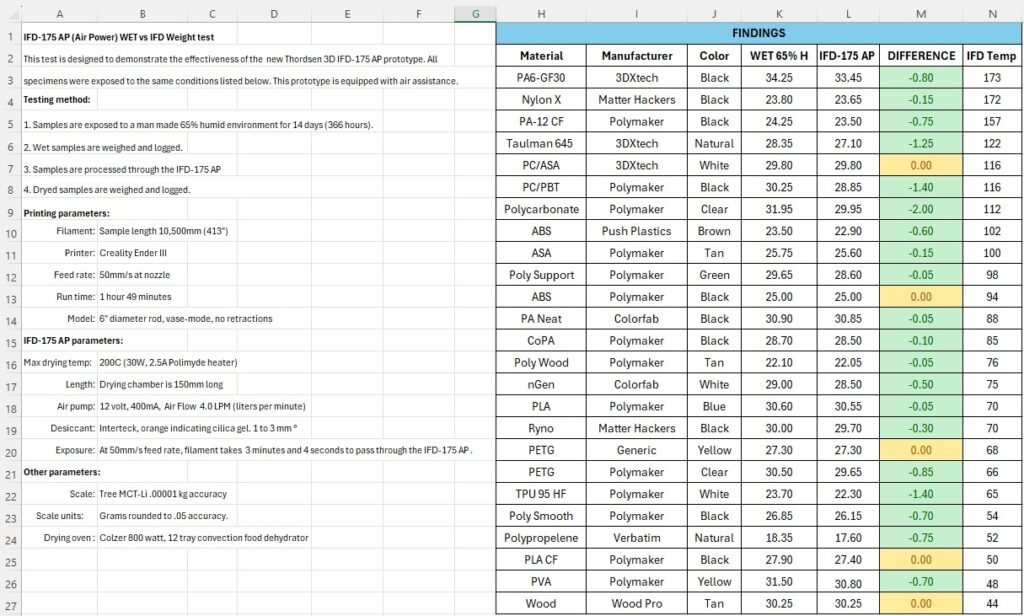

Wet filament vs the IFD-175 AP:

This test demonstrates the amount of moisture the IFD can extract from “wet” material. The material sits in a 65% humidity tub, and then runs through the IFD-175 AP.

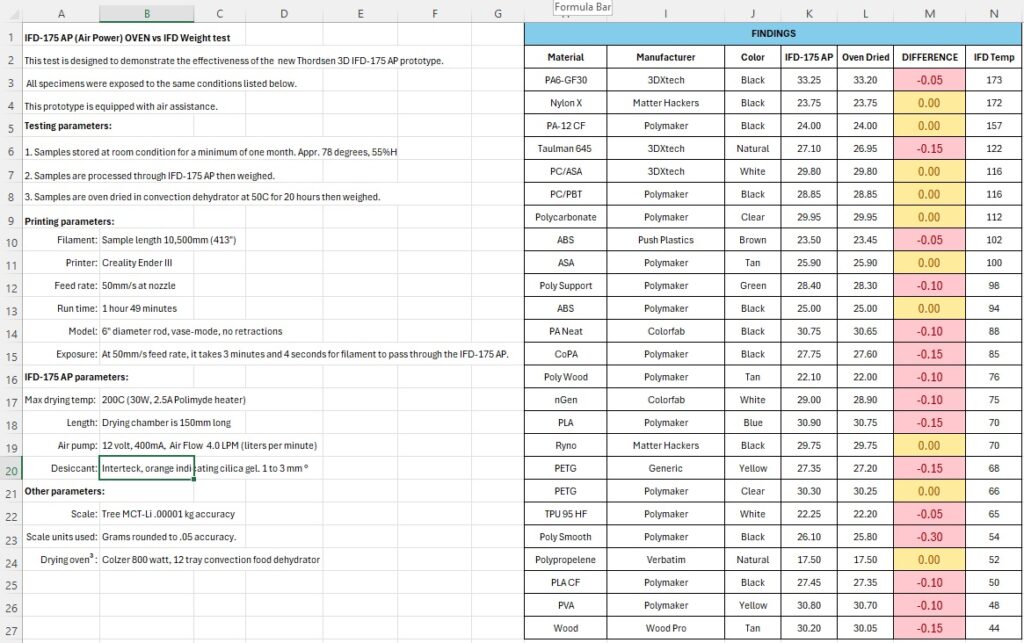

Dehydrator vs the IFD-175 AP: This test demonstrates the difference between material dried in a convection dehydrating oven vs the IFD. The goal was to see whether the IFD can match or come close to matching oven drying.

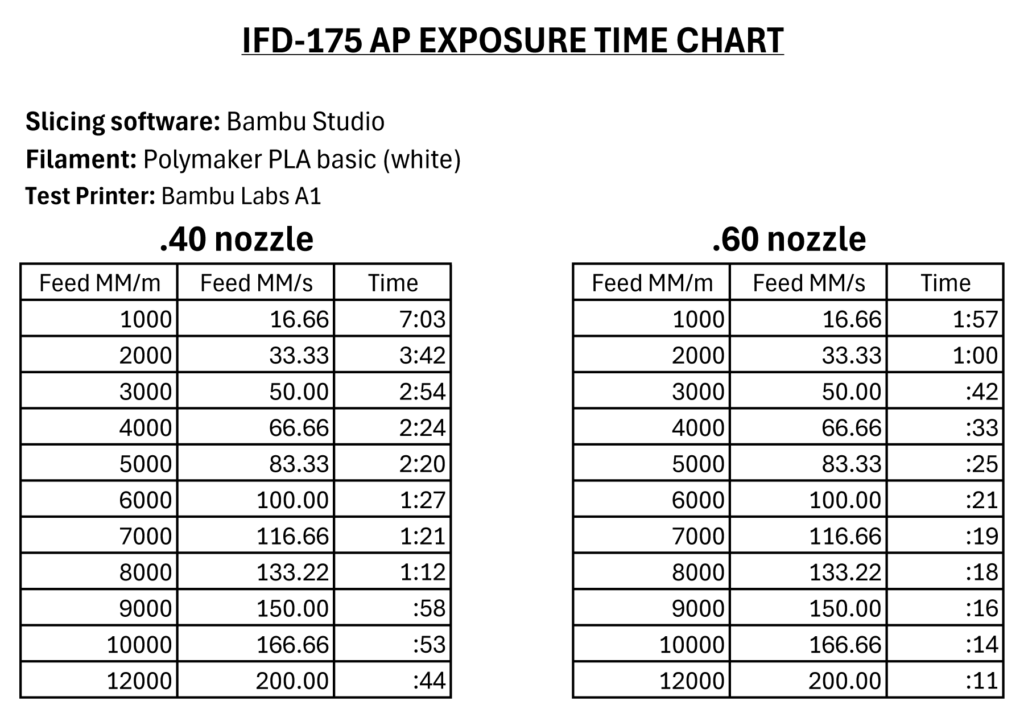

Exposure time:

The longer filament is exposed to heat and air flow, the more moisture that can be extracted. This chart illustrates exposure time for a single strand of material