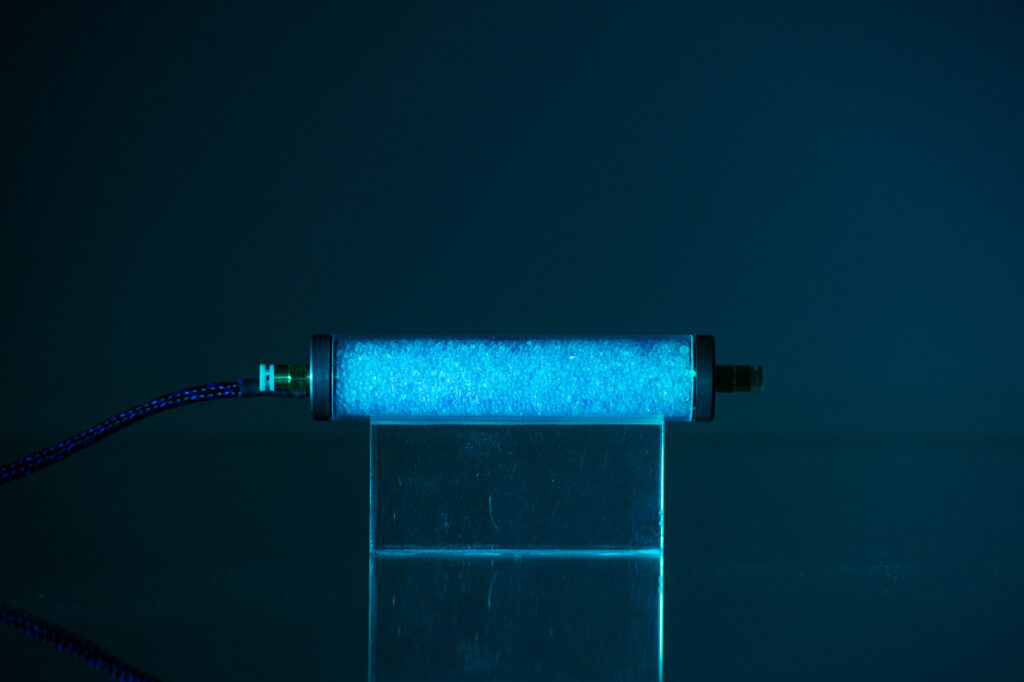

Our new inline filament dryer can be a helpful addition to any 3D printer setup for successful print results. One of the main benefits being that you can dry your filament as you print. Because it uses an inline method, you can be sure that your filament is dried evenly as it runs through, as opposed to drying an entire spool at once where the core does not face the same heat and air exposure. Its small, modular design also makes it versatile for many setups as some print spaces may not have ample room.

Why Moisture Ruins

When it comes to 3D printing, using dry filament is a crucial step for getting clean and precise print results. Wet filament creates small bubbles and pockmarks from moisture quickly evaporating once it hits the nozzle. This creates inconsistencies that affect a print’s strength and appearance. To avoid this, it is best to use a filament dryer.

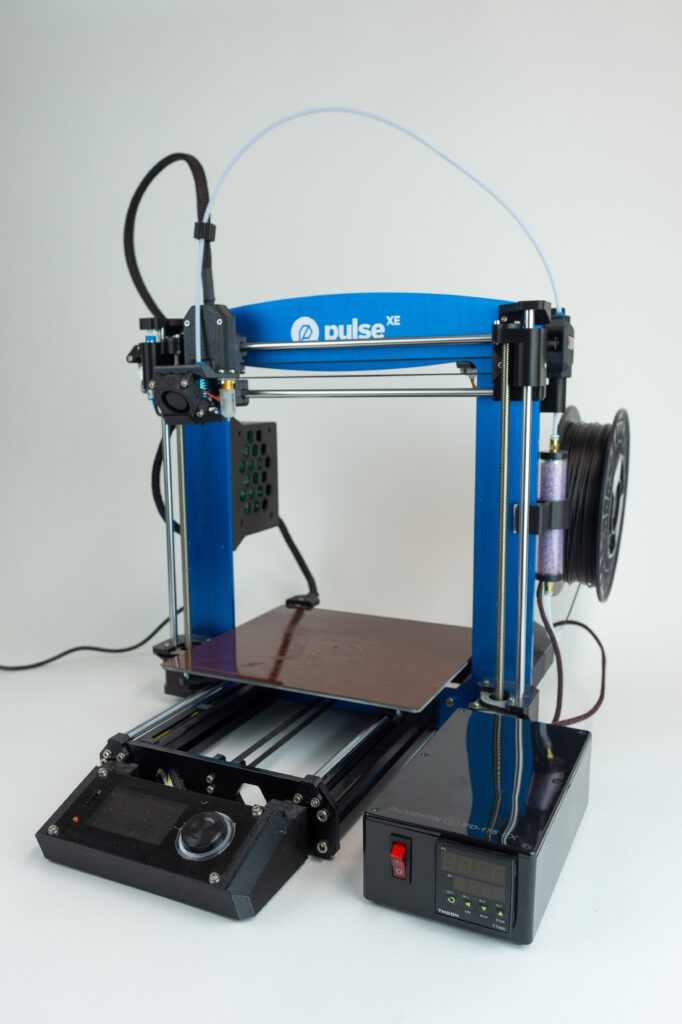

We Get That Space Can Be Tight

The IFD-175 EX was created with space in mind with its small design. Whether you have limited desk space for your printer or a print farm that needs to maximize every inch, our inline filament dryer is space efficient. With the largest part coming in at 7 1/2″ x 4 3/8″ x 2 1/2″ it’s significantly smaller than other dryers and dehydrators.

Ensure A Consistent Dry

With typical filament dryers, the entire spool is dried at once which can create inconsistencies as the outer layers are exposed to the elements more than the core of the spool. This can mean it takes a long time to properly dry the core while the outer layers are baking the entire time. The IFD-175 EX makes this easier by drying the filament by the single strand. This ensures that every inch directly dries at the same temperature and has the same exposure.

Dry Where It Counts

Dry your filament at the most important step, right before the hot end. Drying entire spools, then mounting them to your printer doesn’t ensure it will be dry once it reaches the nozzle. While it’s mounted, it can absorb moisture and become wet by the time it reaches the nozzle. With our IFD-175 EX, the inline design dries the filament just before it gets to the nozzle. This creates the best chance for the filament to stay dry up until the moment it prints.

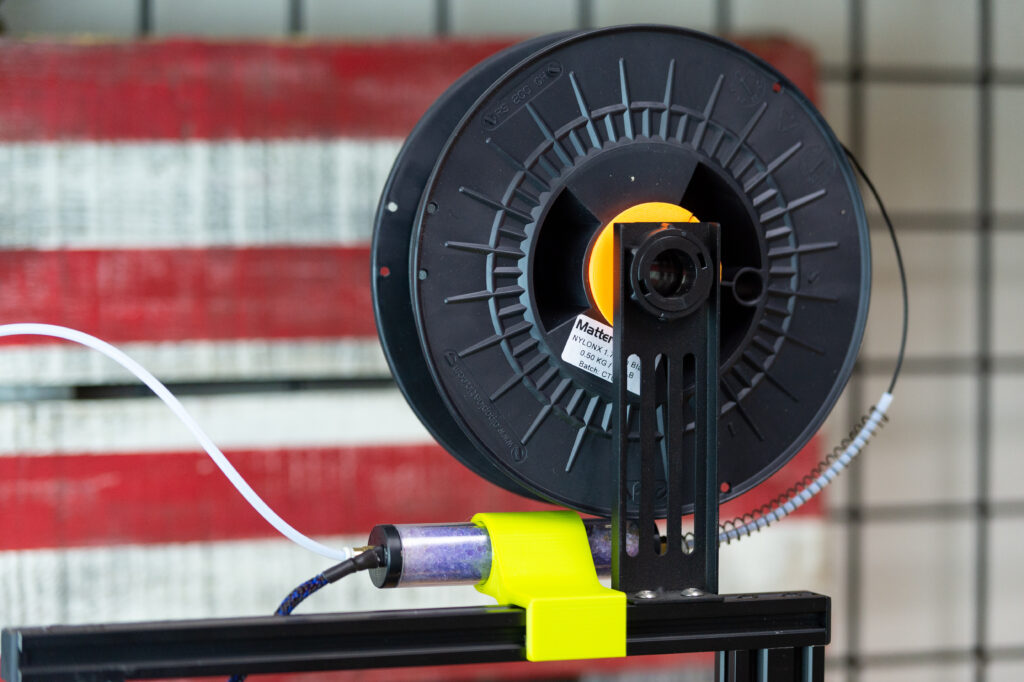

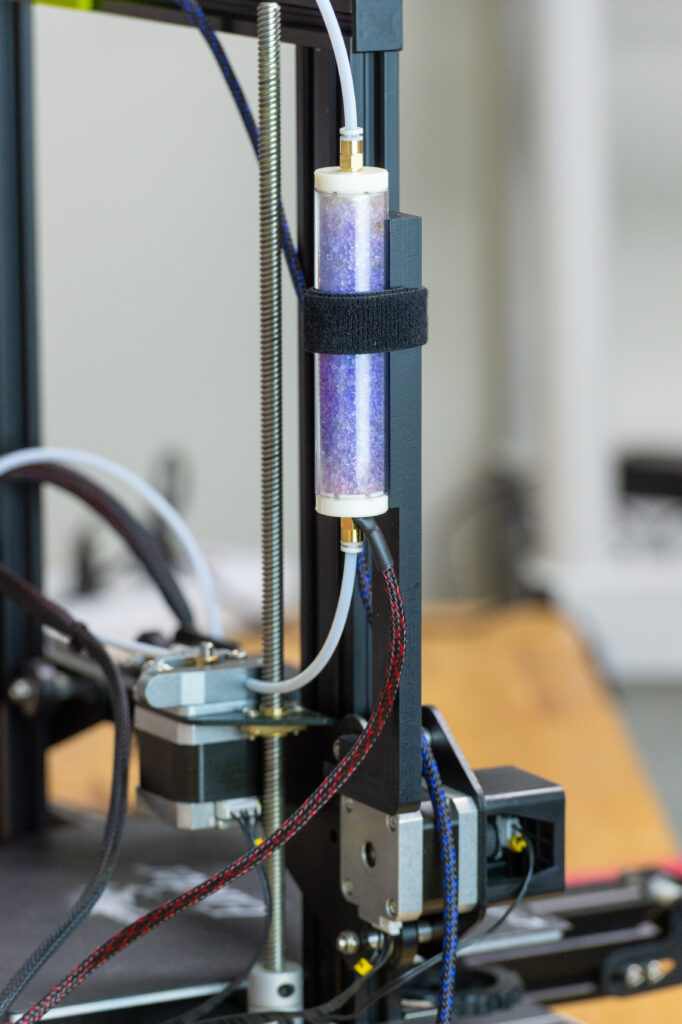

Modularity In Mounting

There are many different printers out there, and with them, many different setups. The IFD-175 EX is modular in design which allows it to be mounted in many different ways. This allows you to find the best way to mount for your specific print setup.