Description

Why does filament need to be dried?

Removing moisture from 3D printing filament is essential for producing high quality, aesthetically pleasing objects. All plastics are porous, therefore, they can naturally absorb moisture from the environment. Heating and compressing plastics, using processes like injection molding or 3D printing, can cause trapped moisture to boil and expand as steam. As the plastic is quickly heated and then cooled, the steam bubbles become trapped and appear as visible defects or internal voids that may compromise structural integrity.

How does it work??

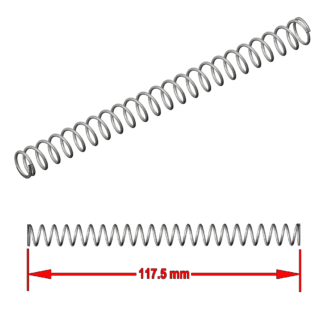

The IFD-175 AP uses heat and airflow to remove moisture from 1.75mm filament. Our custom made 30-watt polyimide heater can reach a maximum temperature of 190°C and incorporates a built in thermostat. The air pump is a continuous use 12-volt fish tank pump. It can move 4 liters of air per minute and is rated by the manufacturer with a 30,000 hour life expectancy. Due to its very low noise at only 58 decibels, we can’t even hear it when our 3D printers are running.

CLICK IMAGE below to view our demonstration video.

Proof of concept:

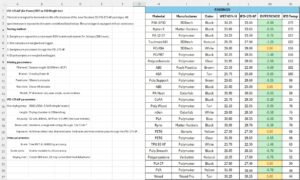

Previous versions of the IFD-175 have proven that the concept of in-line filament drying is feasible. The challenge with the AP model was whether it can keep up with the latest high speed printers and high temperature filaments. We’ve found that testing by weight is the most effective and repeatable method of measuring the dryness of filament. The charts below use 25 common types of filament. The parameters for each testing method are noted in data.

Wet filament vs the IFD-175 AP: This test demonstrates the amount of moisture the IFD can extract from “wet” material. The material sits in a 65% humidity tub, and then runs through the IFD-175 AP.

Dehydrator vs the IFD-175 AP: This test demonstrates the difference between material dried in a convection dehydrating oven vs the IFD. The goal was to see whether the IFD can match or come close to matching oven drying.

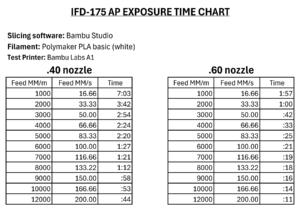

Exposure time:

The longer filament is exposed to heat and air flow, consequently, the more moisture can be extracted. This chart illustrates exposure time for a single strand of material

Adaptability:

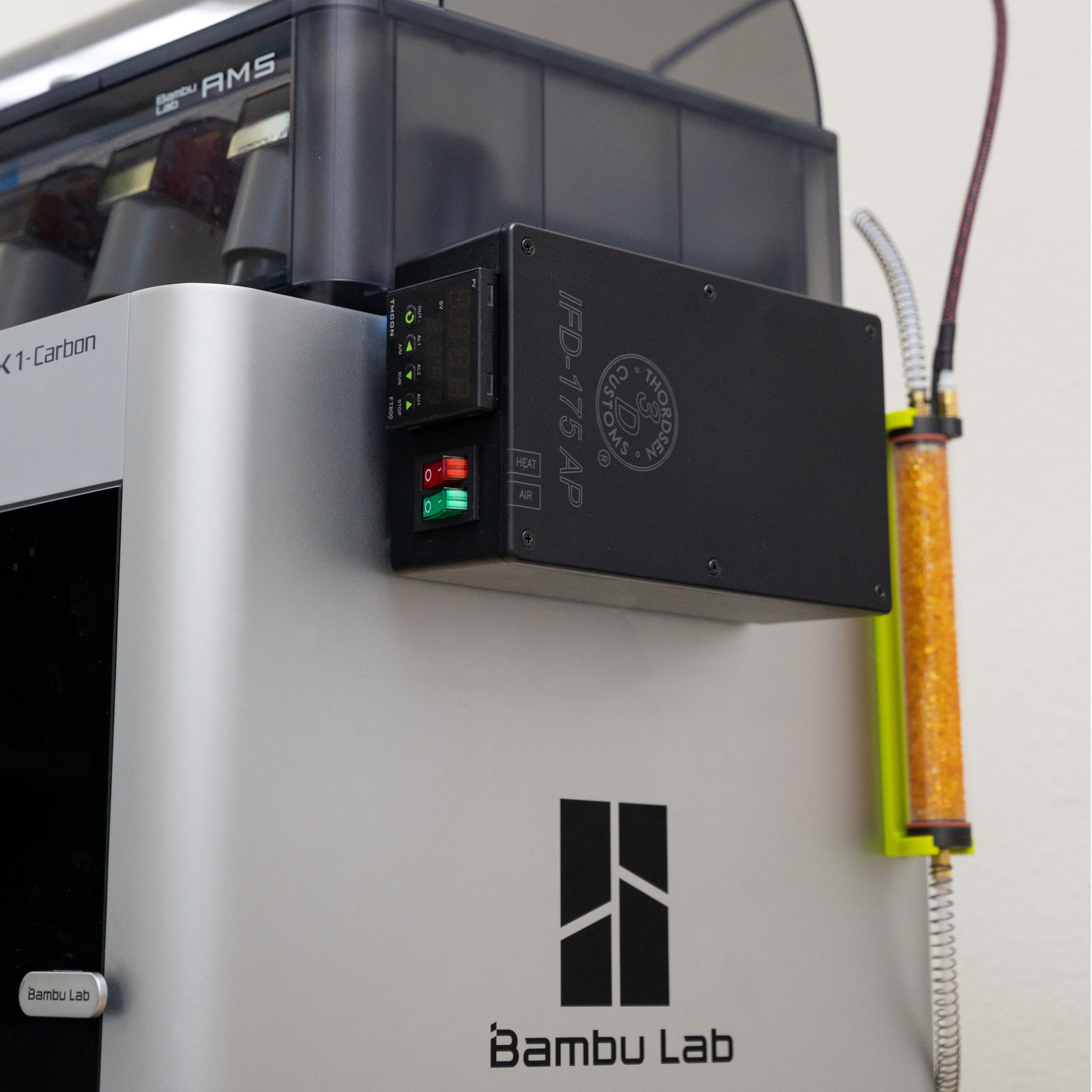

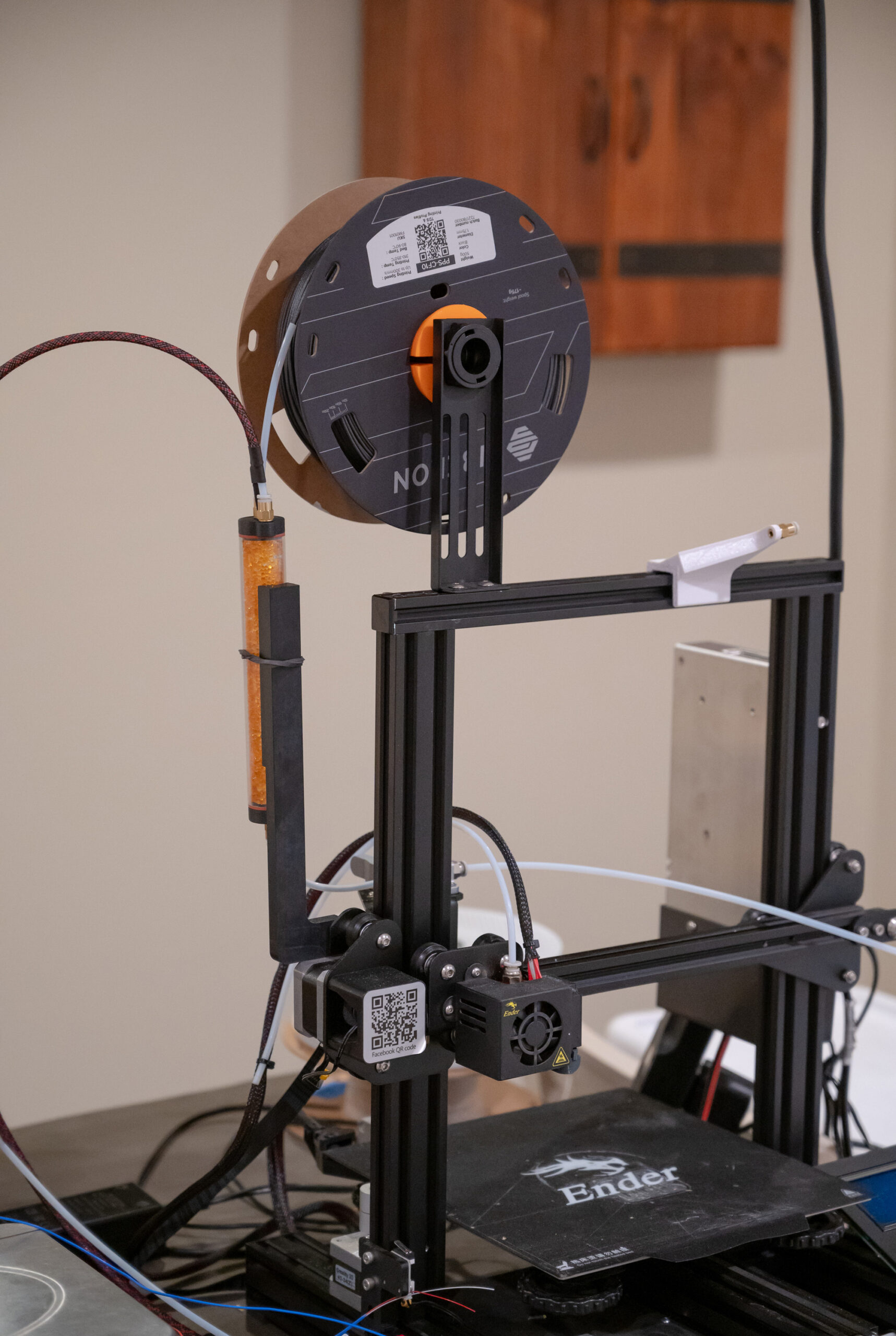

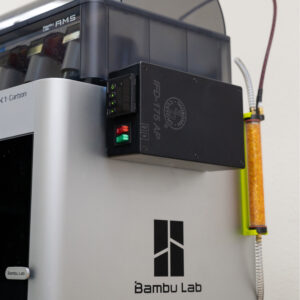

The IFD-175 AP is designed to adapt to virtually any 3D printer on the market. Often times, only a simple bracket is all that is necessary. Unlike traditional filament dryers, the IFD-175 AP is small and allows many variations in how it is set up. Several customers have designed mounts that can be downloaded from our website and on other file sharing websites like thingiverse.com and printables.com.

Reviews

There are no reviews yet.